Filter fabric, QA filters, filter fleece, filter non woven

Filter bag, filter cloth, air filter | Leaks, % open area, blockages

For testing filters, filter fleece, textile fabric filters, or metallic filter fabric with small defects, the recording area of conventional microscopes is too small. The surface microscope Roboscope uses industrial image processing and recognition to find 6µ defects in 150x250mm samples

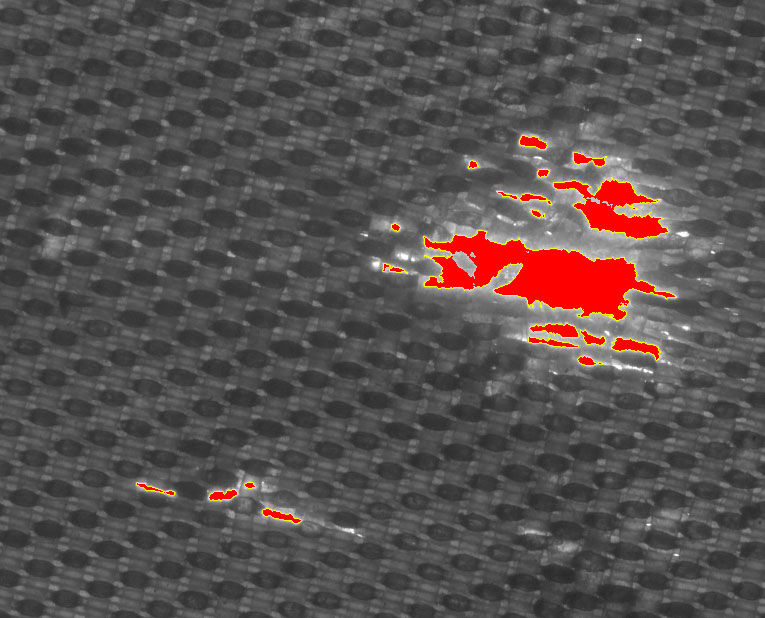

# 1 raw image

Filter mesh with leaks, illuminated with a combination of incident and transmitted light. Sample area 200x300mm.

# 2 marked holes

Damage pattern: leakages found by image recognition are colored red.

Smallest dimension of leaks 10 µm, resolution of the image acquisition up to 4 µm!

# 3 Zoom in on detail

The area and position of defects are calculated. The filter fabric is visible in the background.

# 4 table of results

The calculated position and area of faults can be printed out or exported as a csv file, eg in Excel.

# 5 Zoom in on leakages

Hole shown with a combination of incident and transmitted light, dimensions in mm. The dimensions are accurate to 0.01 mm, without parallax error!

# 6 Filter bag partially blocked, filter cake

Which percentage of the filter bag is still permeable? Color or black&white images possible

# 7 Zoom in on abrasion

The fact that the weft threads of the filter bag are still intact suggests that abrasion was the cause of the error.

# 8 Non woven air filter

The image recognition calculates the area of the pores and sorts them according to their size.

# 9 Zoom air filter

The area calculated by the image recognition can be found in the pop-up window (for pore no.21, upper edge of the image)